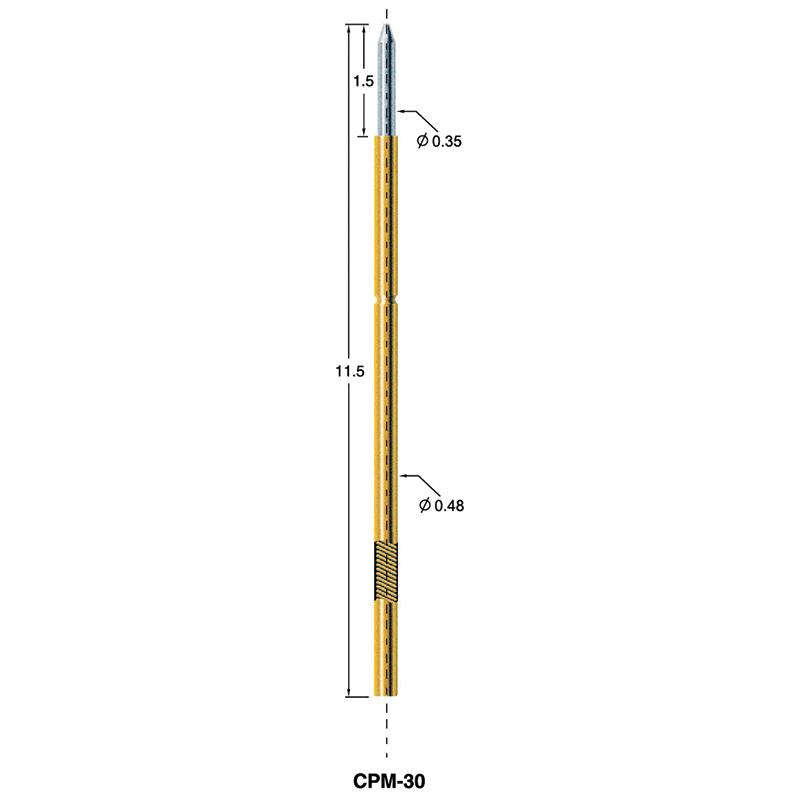

CPM-30

Welcome to contact us.

Unit : mm

| Mountiong hole size |

| Φ 0.65 /.0256” |

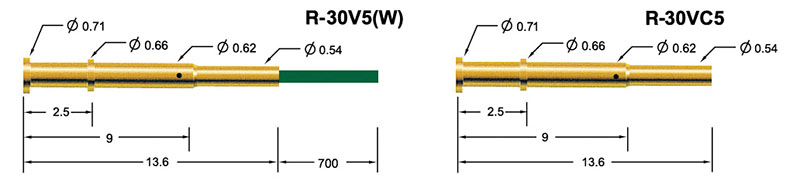

| Probe specifications CPM-30/R-30 | ||

| Recommended min. center | 0.85 (.0335") | |

| Full travel | 1.5(0.059" )/2(0.787" ) | |

| Current rating | 1A | |

| Contact resistance | 150mΩ | |

| Spring force | 30g / 70g | |

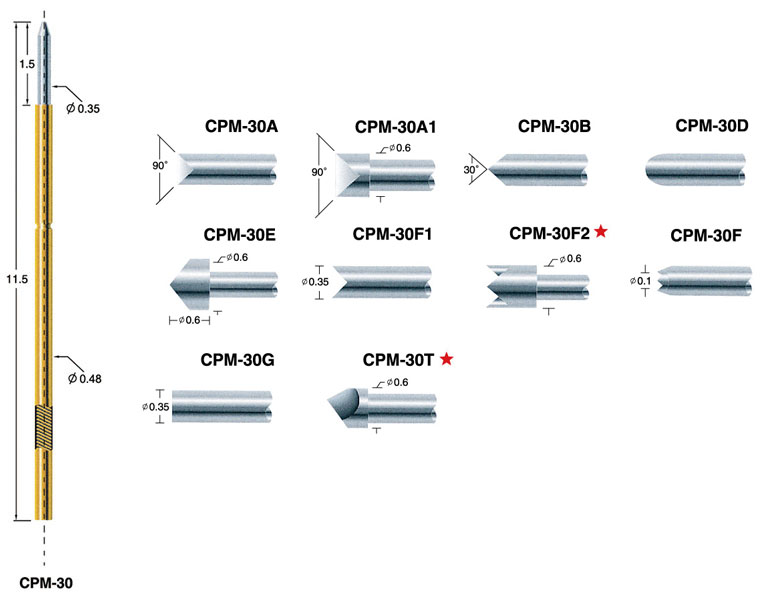

| ★ code for customized products | ||

| Materials and finishes | ||

| Plunger | SK4, Ni plated | |

| Barrel | Phosphor bronze, Gold plated | |

| Spring | Stainless Steel | |

During the mounting process, the probe requires a specific hole size for proper installation. In this case, the recommended mounting hole size is Φ 0.65 /.0256". This ensures a secure and accurate fit, enabling precise testing and analysis of the PCB.

The Bare Board Test Probe, specified as CPM-30/R-30, follows precise specifications to deliver reliable results. The recommended minimum center distance between probes is 0.85 (.0335"), ensuring proper spacing for effective electrical connections and avoiding any interference.

The probe has a full travel distance of 1.5 (0.059") or 2 (0.787"), indicating the maximum extent to which it can move during testing. With a current rating of 1A, it can handle electrical currents up to 1 ampere, making it suitable for a wide range of applications. The contact resistance is specified as 150mΩ, ensuring low resistance and efficient signal transmission. The spring force can be adjusted between 30g and 70g, providing flexibility based on the specific testing requirements.

The materials and finishes used in the construction of the Bare Board Test Probe are carefully chosen to ensure durability and optimal performance. The plunger is made of SK4 and is Ni plated, offering excellent conductivity and corrosion resistance. The barrel is constructed from phosphor bronze and is gold plated, preventing oxidation and maintaining a reliable electrical connection. The spring is made of stainless steel, known for its strength and longevity.